-

صفحة رئيسية > المنتجات >

jaw crusher detector

2020-04-08T21:04:16+00:00

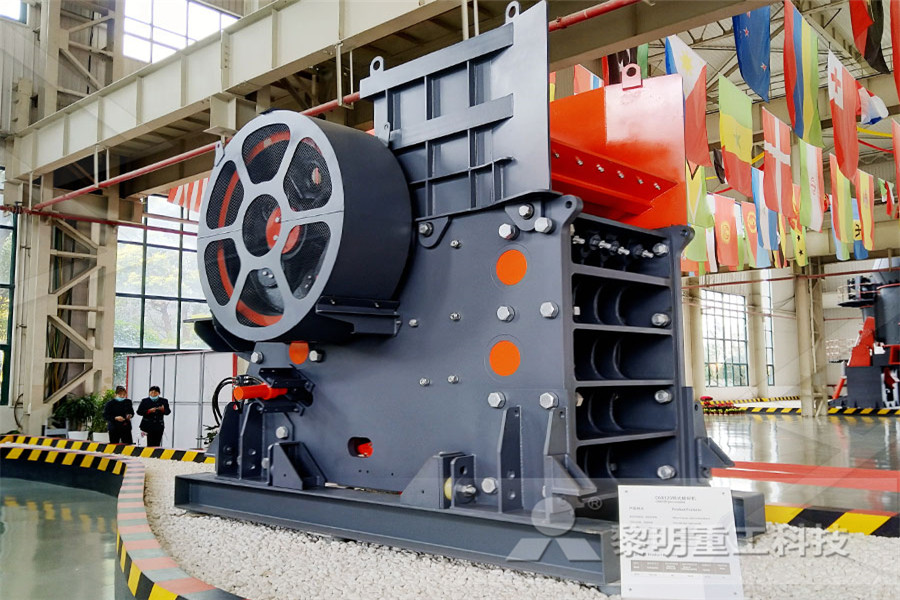

C Series Jaw CrusherMECRU

Work Principle When working, the motor drives the belt and the pulley, and moves the movable jaw up and down through the eccentric shaft When the movable jaw rises, the angle between the toggle plate and the movable stationary primary secondary Capacity: 11 t/h 30 t/h Motor power: 11 kW 30 kW Jaw Crusher is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industriesIt is suitable Jaw crusher, Jaw crushing and screening plant All A jaw crusher and testing mechanism technology, applied in grain processing and other directions, can solve the problems of high manufacturing and operating costs, Jaw crusher with detection function Eureka Patsnap

Jaw Crusher,Jaw Crusher Manufacturer,Jaw

2023年9月26日 Jaw Crusher Introduction This series of jaw crusher can reach the crushing ratio of 46 and the shape of final product is even They are widely applied to crush high hardness, mid hardness and soft rocks Herzog jaw crushers are designed as jaw crushers equipped with one movable and one fixed breaking jaw This involves pressing the material to be crushed through the moving Herzog Maschinenfabrik: CrushingWe are noted Manufacturer and Supplier of an enhanced quality Jaw Plate, Crusher Idler, Crusher Roller, etc The offered products are widely demanded for their rugged Manufacturer of Crusher Magnets Crusher Metal Detector

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher Scroll Top 26 Yaldwyn Road Witfield / Jet Park Boksburg South Africa 27 11 842 5600 Primary Menu Our Products Jaw Crushers Cone Crushers VSI Crushers HSI CrushersJaw Crusher For Sale Stone Crushing Machine Pilot CrushtecProvided by the Springer Nature SharedIt contentsharing initiative Granularity condition assessment is essential when developing an intelligent realtime monitoring system of Granularity Detection in Images of Feeding or Discharging in Jaw

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse ® C Series™ jaw crushers 1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one What Is A Jaw Crusher MEKA

Everything you need to know about Crushers in Cement

A jaw crusher designed for a certain throughput rate can accept larger pieces of rock than the normal gyratory crusher In order to cope with equally large – sized feed, the gyratory crusher has to be over – designed in terms of capacity Magnetic separators and metal detectors are used for the purpose and help more particularly to For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionJaw Crusher Explained saVRee2023年6月5日 Product Description High manganese steel jaw crusher wear parts Shanghai Chenglei Mining Machinery Co, Ltd, one of the biggest casting foundry in China! Our company was founded in 1993, specialized in design and manufacture wear parts for crushers, such as Jaw Plates, Bowl Liner, Liner, High Chromium Blow Bar, Connector [Hot Item] 1100X650 Fixed Jaw Super Tooth 6002148e

Dust Suppression System on Mobile Crushing Plants

Jaw Crusher Capacity 350 tph 385 TPH: RM HS3500M; Mobile Scalping Screen Capacity 200 tph 220 TPH: RM HS5000M; Mobile Scalping Screen Capacity 300 tph 330 TPH: RM HS7500M Without using your crusher dust suppression system, you run into OSHA/MSHA issues; risk being shut down;2023年6月21日 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw Jaw Crusher SpringerLink2022年11月21日 Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate The kinematics of this type of toggle system result in a higher capacity than that achieved with a doubletoggle jaw Industrial Solutions Jaw crushers ThyssenKrupp

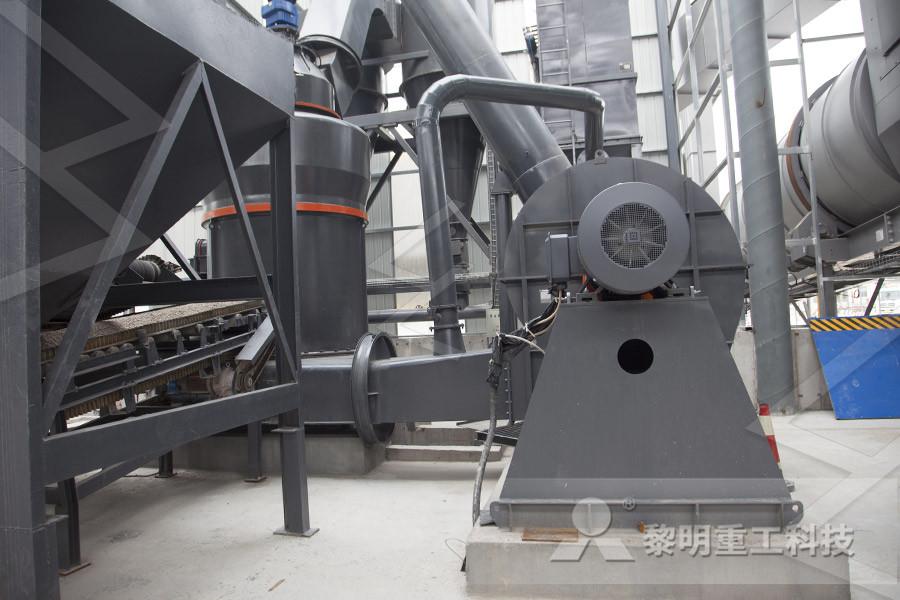

(PDF) Automation experimental studies of grinding process in jaw

2018年12月1日 The grinding process in the jaw crusher was chosen as the process for the study Conducting experimental studies of crushing processes is a timeconsuming process that takes considerable time2023年10月31日 1 In order to achieve a higher output, the user increases feeding capacity, which results in jaw crusher blockage 2 Too much material in the lower chamber of the jaw crusher can't be discharged, so How to quickly solve jam problem in jaw crusher?With its new mobile cone crusher MOBICONE MCO 90i EVO2, has created the perfect supplement to the jaw crushing plant MOBICAT MC 110i EVO2 MCO 90i EVO2 For the cone crusher MOBICONE MCO 90 (i) EVO2 and the impact crusher MOBIREX MR 110 (i) EVO2, doubledeck post screening units for two final products are now availableMCO 90i EVO2 Mobile cone crushers Wirtgen

Jaw Crushers Best Models for 2023 911 Metallurgist

1 天前 Metal Detectors; Placer Mining; Hardrock Plants; Filtering/Drying Pressure Filters; Vacuum Drying Ovens; Pulverizers Mortar Pestle; Splitters/Dividers; Rollers; Smelting Small Laboratory Jaw Crusher US $ 7,000 $ 6,350 Add to cart; Sale! 3″ x 4″ Gasoline Rock Crusher US $ 12,000 $ 10,000 Sale! 3″ x 4″ Electric Small Rock CRUSHER: JAW CRUSHER: China: Nhava Sheva Sea: SET: 1: 390,440: 390,440: Nov 17 2016: : PE6090151 SWING JAW PLATE SHIM (CRUSHER MACHINE PARTS) China: Banglore Air Cargo: PCS: 1: 14,786: 14,786: Nov 10 2016: : 2 LINKS X 10MM GRADE80 LIFTING C/W CLEVIS SHACKLE ONE END AND 1 EYE Import Data and Price of jaw crusher under HS Code 8474March 28, 2019 / in News A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarry What Are Jaw Crushers and How Do They Work? Oreflow

rock crusher Miscellaneous Goods Gumtree Australia Free

Dirt rock screen crusher 40 ft hydraulic 8x4 flatbed screen , hatz diesel all hydraulic ,goes well $30,000 gst also 250x200 rock crusher jaw type as new $8000 gst Ph $33,000 Briagolong, VIC 23/06/2023 portable mini rocker crusher, gold prospecting, mining Cobbers crusher mini rock crusher turns your 5” (125mm) angle grinder into a mini The Jaw Crusher HSC 50 / MT was developed for the rapid but gentle crushing of mediumhard, hard, brittle and tough materials After the funnel has been filled, the metal detection, the separation of the metal contained sample material and Herzog Maschinenfabrik: HSC50 / MT: Manual jaw crusher with metal detector2023年11月3日 The fuel efficient direct drive Finlay® C1540 Cone Crusher is the optimum machine for medium sized producers and contract crushing operators This efficient and productive machine features the proven Finlay® 1000 cone crusher that is choke fed with integrated level sensor, automatic tramp relief and hydraulic closed side setting (CSS C1540 Direct Drive Cone Crusher Mobile Tracked Crusher

How does a Rock Crusher Work Jaw Crusher 911

2021年11月22日 BACK VIEW—SWING JAW FOR 36 by 25 INCH CRUSHER Notice the extra length of this jaw as compared to conventional types Designed up to onethird longer, it exerts greater pressures in the upper portion of the crushing chamber, distributes crushing action more evenly The result is a gradual reduction of ore to the choking point, and TERMINATOR Jaw Crusher Model JCT#1AL Automatic Lubrication, capacity 5" X 7" Unit, equipped with one set of smooth or serrated jaws (alloy 1 or 2), 208/220/440/575 volt, 3 phase, 60 cycles, 5 HP motor, automatic lubricating system also powered by electric motor, accessories for adjustment of jaws, and rubber mat for underneath crusherTM Engineering Terminator Jaw Crusher Secondary Jaw 2019年9月2日 The reduction ratio for a jaw crusher is typically 6to1, although it can be as high as 8to1 Jaw crushers can process shot rock and gravel This ability to accurately set the crusher aprons from the PQ University Lesson 7: Crushing Secondary

® C Series™ jaw parts

2018年10月15日 C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are crushed in a single layer, referred to as singlelayer crushing Smaller particles are crushed rock on rock, referred to as multilayer crushing C Series™ jaw crusher basic The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double McLanahan Jaw Crushers2022年9月20日 The plate dimensions of the unoptimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig 3The load and boundary conditions for the static structural analysis were as shown in Fig 4Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were Optimisation of the swinging jaw design for a single toggle jaw crusher

Jaw Crushers Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, fullenclosure guards, all integrated on a steel skid Oversized bearings and castings, robust construction, longwearing cast manganese steel jaw plates Optional steel stand Sizes: 6”x 10” through 20” x 30″ jaw opening Discharge size: ranges from 3/4” minus through 4 2 天之前 Description A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPE Laboratory Jaw Crusher 911 Metallurgist2019年4月29日 TN77 Metal Detector operating in an aggregate quarry The design of metal detector or magnetic separator is dependent upon the application Understanding the nature (eg size, shape, composition, origin) of the tramp metal is important Typical tramp metal will include digger teeth, drill rods, crusher plates, bars, chains, nuts and boltsDetecting and Removing Conveyed Tramp Metal Bunting

Mobile Cone Crusher, Cone Crusher Plants Supplier at

Puzzolana offers a track cone plant range with a compact, efficient and high output Cone Crusher Plant With its userfriendly design and quick setup time, it is ideally suited for Indian mining and quarrying Metal detector; Choke feeding; Dust suppression system; Brochure Form Submit Mobile Jaw PTJ 1176; Mobile Screen PTS 15523 2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the (PDF) Influence of jaw crusher parameters on the The MOBICONE MCO 110i PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance As an option, the plant can be operated via an external power source and impresses with its lowmaintenance operation Extremely robust design Very high production outputs with lowmaintenance operationMCO 110i PRO Mobile cone crushers Wirtgen

Assessing the energy efficiency of a jaw crusher Request PDF

2014年9月1日 The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpmWelcome to Roljack group, We feel pleasure in introducing ourselves as leading manufacturers of all type of Stone Crusher, Jaw Crusher, Cone crusher, Mobile Crusher, Impact Crusher HSI VSI, Vibrating Screens And Crushing plants, Marble processing equipments All types of Construction equipments Metal Detectors etc This plant ROLJACK ASIA LIMITED WELCOME TO ROLJACK GROUP2019年6月26日 The ® Pegson XA750 jaw crusher is one of the most advanced and efficient tracked crushing plants on the market for large scale operators The Pegson XA750 is capable of producing high volumes of • Metal detector • Dust suppression system • Economical to operate with a highly fuel efficient direct drive systemCrushing Product Range Environmental

JCE系列欧版颚式破碎机 JCE Series Jaw Crusher SKJ

2013年5月20日 working performance and service life, etc JCE Jaw Crusher has become the most popular product in the world, which is the first choice to crush hard materials 产品简介 Product Introduction SKJ Series Jaw Crusher JCE系列欧版颚式破碎机 13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics2 天之前 Available in a variety of sizes and configurations, the HydraJaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver highcapacity crushing and reliable performance for increased operational productivity and profitability Our diverse line of industryleading jaw crushers offers producers the latest in jaw crushing technology Jaw Crushers Astec

jaw crushercqdj3755的博客CSDN博客

2013年8月19日 jaw crusher ,a crusher machine used for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa According to information statistics,in recent years,as China's economic construction and the allround development of infrastructure construction,the need for sands is also more and more Astro JawE Crusher Features of the Astro JawE Crushing Equipment Large Crushing Capacity with New “V” Chamber Design The newly designed “Vshape” crushing chamber ensures the Jaw Crushers ability to withstand large capacities of feed material, while Its reversible, corrugated jaw plates create a nonchoke configurationEarthtechnica (Kawasaki/Kobe) MinproviseThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 Jaw Crusher an overview ScienceDirect Topics

® C Series™ jaw crushers

The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse 1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one What Is A Jaw Crusher MEKAA jaw crusher designed for a certain throughput rate can accept larger pieces of rock than the normal gyratory crusher In order to cope with equally large – sized feed, the gyratory crusher has to be over – designed in terms of capacity Magnetic separators and metal detectors are used for the purpose and help more particularly to Everything you need to know about Crushers in Cement

Jaw Crusher Explained saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension2023年6月5日 Product Description High manganese steel jaw crusher wear parts Shanghai Chenglei Mining Machinery Co, Ltd, one of the biggest casting foundry in China! Our company was founded in 1993, specialized in design and manufacture wear parts for crushers, such as Jaw Plates, Bowl Liner, Liner, High Chromium Blow Bar, Connector [Hot Item] 1100X650 Fixed Jaw Super Tooth 6002148eJaw Crusher Capacity 350 tph 385 TPH: RM HS3500M; Mobile Scalping Screen Capacity 200 tph 220 TPH: RM HS5000M; Mobile Scalping Screen Capacity 300 tph 330 TPH: RM HS7500M Without using your crusher dust suppression system, you run into OSHA/MSHA issues; risk being shut down;Dust Suppression System on Mobile Crushing Plants

Jaw Crusher SpringerLink

2023年6月21日 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw 2022年11月21日 Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate The kinematics of this type of toggle system result in a higher capacity than that achieved with a doubletoggle jaw Industrial Solutions Jaw crushers ThyssenKrupp2018年12月1日 The grinding process in the jaw crusher was chosen as the process for the study Conducting experimental studies of crushing processes is a timeconsuming process that takes considerable time(PDF) Automation experimental studies of grinding process in jaw

jaw crusher detector

C Series Jaw CrusherMECRU Work Principle When working, the motor drives the belt and the pulley, and moves the movable jaw up and down through the eccentric sh