-

صفحة رئيسية > المنتجات >

Phosphate Rock Ore Vibrating Screen

2023-01-17T21:01:06+00:00

Phosphate Rock Processing: 6 Useful Ways and 4

2023年8月8日 Phosphate rock is transported to the raw ore bin and enters the jaw crusher through the vibrating feeder After coarse crushing, phosphate rock enters the cone crusher again for medium and fine Phosphate Rock When phosphate rock, phosphorus concentrate, and fluxes are smelted in an electric arc furnace under temperatures of 1400–1500°C (2552–2732°F), molten slag Phosphate Rock an overview ScienceDirect TopicsThis heavyduty vibrating screen for fertilizer is four feet wide by eight feet in length It has dual, topmounted industrial vibration motors that shake the Vibrating Screen Scalps Phosphate Rock at a Rate

Phosphate Rock an overview ScienceDirect Topics

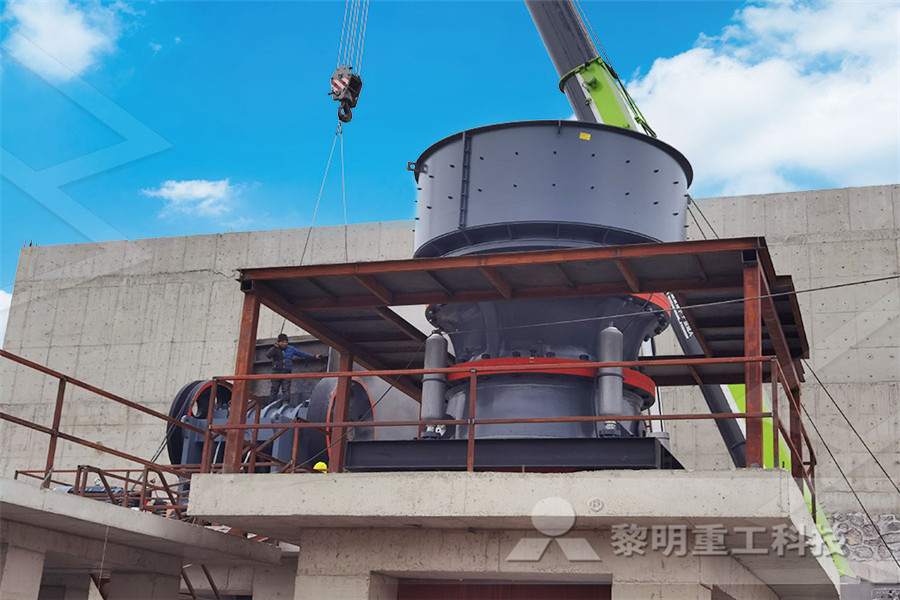

Rock phosphate Rock phosphate is a naturally occurring ore of marine sedimentary origin It may have a composition of 0300, but the grade is noted as 030, since rock phosphate 2023年10月24日 Phosphate Applications Its primary use is in the agricultural industry Crucial to fertilizers, phosphate rock represents the building block of the fertilizer industry The calcium phosphate imbues Phosphate Rock Fertilizers: Manufacturers, 2018年1月25日 Phosphate ore coarse crushing often uses jaw crusher or gyratory crusher, middle size crushing often use cone crusher, screening often uses circular vibrating Phosphate Ore Mining Process Equipment and Technology

Phosphorite Ore Crushers Selection Eastman

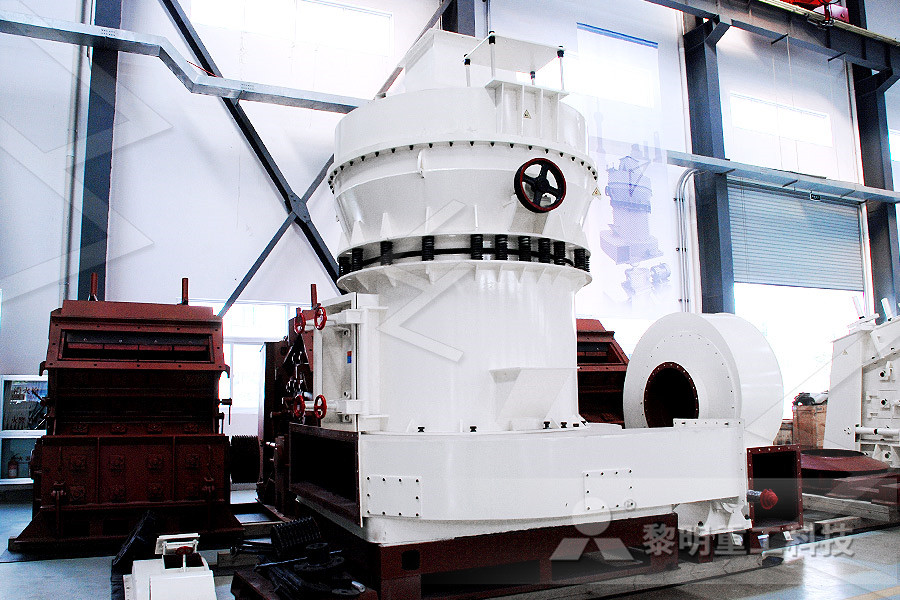

Phosphorite Ore Crushers Selection Ore properties In the selection of phosphate ore crushing and screening equipment, should be fully considered the hardness and particle size of the ore crushing stage 2022年5月16日 The large pieces of phosphate rock are evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for Phosphate rock grinding process SHANGHAI CLIRIK 2017年10月25日 Vibrating Screen for Copper Ore Processing The copper ore is then ground finely before the copperbearing sulphide minerals are concentrated by a flotation Vibrating Screen Sale for Coal Mining ,Copper Ore Processing

Vibrating Screen Mineral Processing

2023年10月30日 Overview Introduction: The vibrating screen is a mechanical device for screening, classifying and filtering granular materials, commonly used in mining, industry and laboratories It is mainly used for 2023年10月28日 Wet pan mill is the optimal first grinding equipment for the majority of smallscale rock gold processing plants, alternative equipment for ball mills Wet pan mills are usually connected with equipment such as crushers, centrifuges, and shakers It is widely sold in most African countries such as Sudan and ZimbabweWet Pan Mill Mineral Processing2023年10月20日 There are many factors affecting the work of the shaking table, among which the main stroke, the number of strokes, the concentration of ore feeding, the amount of ore feeding, the flushing water for the ore body, the lateral slope of the bed surface, and the nature of the ore feeding (1) Stroke and stroke timesFactors That Affecting Shaking Table Gravity Separation

DMS Mining Process, Equipment Mineral Processing

2023年11月1日 DMS(dense medium separation) is an efficient and widely used technique, especially useful for separating valuable minerals with relatively high gangue densitiesIt is often used in the processing of diamonds, coal and various base metal ores The mineral DMS process enables the mining industry to increase overall recovery efficiency by 2023年10月20日 2 Grinding process The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing Here also need to use an auxiliary equipment – classifier It can classify and screen copper ore and release copper ore powder that meets the requirements 3Copper Ore Processing Plants, Flow And Equipment2023年11月1日 Leadzinc ore usually exists in the form of sulfide ores, such as sphalerite and galena Flotation is the most commonly used method The leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravityflotation, magneticflotation, and gravitymagnetic Lead Zinc Processing Solution Mineral Processing

Tin Ore Processing Plant Mineral Processing

2023年11月3日 1 Crushing: The material less than 15mm enters the hopper with a grizzly screen, then is fed by the trough feeder, and is transported to the jaw crusher and roller crusher through the belt conveyor, and is crushed twice to reach the ideal size 2 Screening: Qualified materials are screened by vibrating screen, materials less than 5mm enter the 2023年10月28日 JXSC Mine Machinery Factory Tel: +86 Email: sale@jxscmachine Phosphate Rock processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designPhosphate Rock Processing JXSC Machine2022年1月21日 This study contributes to enlarge data about sedimentary phosphate rock extraction and beneficiation globally as currently only the USA and Morocco were reported in databases (1 kg crude ore contains 27% P 2 O 5), and the USA, where the average The scrubber, the vibrating screen, the hydrocyclone, and the filtration use electric Cradletogate life cycle assessment of beneficiated phosphate rock

Ultimate Guide To Ore Washing JXSC Machine

2019年10月25日 2 Vibrating washing screen vibrating screen product Mine use vibrating screens often adopts doublelayer screens for screening medium and fine crushed ore Add a highpressure water flushing device on the fixed screening machine The flushing water pressure is generally 0203 MPa, and the water consumption per ton of ore is 1 ~ 2 m31 天前 Introduction: In gravity separation, the shaking tables (gravimetric tables, shaker tables) are the most widely used and efficient sorting equipment for fine ore separation The shaking table beneficiation is not Mining Shaking Tables Gravity Separator2015年7月26日 A vibrating mechanism attached to the middle of the screen imparts rapid vibrations of small amplitude to its surface, making the ore, which enters at the top, pass down it in an even mobile stream The Vibrating Screen Working Principle 911

Vibrating Feeder Mineral Processing

2023年10月28日 The vibrating screen feeder is mainly used in the following situations: (1) It can be continuously fed before coarse crushing and screening to separate fine particles and improve crushing capacity 2023年10月26日 Main equipment: trommel screen and gold sluice box The trommel screen can wash, screen, and remove mud in rocks, and the sluice box captures fine gold and nuggets The sluice box can be customized to 2m, 4m, or 6m in length, 1m or 05m in width Application: The setup is suitable for washing alluvial gold ore without sticky clay Mobile Gold Wash Plant Mineral Processing2021年11月1日 The raw phosphate ore was crushed and milled using a ball mill and then sieved to different size fractions (61– 75 μm, 75– 88 μm, 88– 100 μm, 100– 125 μm, 125– 150 μm, 150– 180 μm, 180– 200 μm, 250– 300 μm) by an electric vibrating screen after drying at 110 °C for 12 hPhosphate ore particles dissolution kinetics in ScienceDirect

Feldspar Processing Plant Mineral Processing

2 天之前 Raw feldspar ore information: contains iron, calcium, mica, and other impurities, so the feldspar ore dressing process including magnetic separation, flotation or gravity separation, so as to remove iron, mica and other impurities to obtain highgrade feldspar 1 Crushing section: Utilize coarse jaw crusher, fine jaw crusher and vibrating screen to 2022年8月7日 Vibrating Screen delivers rocksolid dependability It’s ideal for environments with high production volume but limited space, and is available in single, double, and triple decks With rugged construction and smart customization options, it gives you everything you need for worryfree work Troublefree Heavy duty EfficientTabor Horizontal Vibrating Screen Efficient Elgin 2023年11月2日 Gold CIP Processing The gold CIP ( CarboninPulp ) is widely used to extract gold from ore It mainly involves using activated carbon to adsorb gold from a cyanide solution, then eluting and regenerating the carbon for reuse It is mainly suitable for beneficiating goldcontaining oxidized ore with high slime content and containing carbon Gold CIP Processing Solution Mineral Processing

Types of Stone Crushers Machine Mineral Processing

2023年10月20日 Roller crusher is a very old crushing equipment that appeared in 1806, and its structure is simple It can crushers iron ore, Quartz Stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, Kalbite, limestone, river pebbles, copper ore, bauxite, barite, basalt, etc2023年10月20日 Attention to these four points can greatly improve the flotation efficiency of tin ore Firstly, please select the appropriate collector and adjust its dosage according to the characteristics of the ore Second, control the pH value and add appropriate activators and inhibitors Third, ensure proper pulp density and stirring speedFour Points To Improve Tin Ore Flotation Recovery Rate2016年5月9日 Lithium Ore (Spodumene) Flotation The conditioned pulp is diluted to approximately 20% solids for flotation in “SubA” Flotation Machines of standard steel construction The cell to cell type machine Processing Spodumene by Froth Flotation for

Breakthrough In High Grade Rutile Beneficiation

2023年10月27日 1 Crushing: The shape of the natural rutile ore is relatively large, so the jaw crusher must be used for preliminary crushing, and a vibrating feeder is also needed at this time The vibrating feeder is 2023年10月20日 iron ore contain high sulfur, phosphorus Beneficiation The common processes used to remove sulfur from iron ore concentrates are flotation and roasting At the same time, the latter is costly and produces environmental pollution, so the main direction of research is to strengthen flotation A large number of research results prove that iron Various Types Of Iron Ore Beneficiation Processes2023年11月3日 The main gravity beneficiation equipment is jig concentrator, shaking table, spiral separator, and gold concentrator It can processing various minerals such as gold, copper, leadzinc ore, tantalum, niobium, tin, and tungsten, etc Strong adaptability, high sorting recovery rate and low costGravity Separation Equipment Mineral Processing

Jaw Crusher Mineral Processing

2023年11月2日 Introduction: Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with a capacity range of 11000tph There are two types of feeding 2023年10月31日 CIL (Carbon In Leach) is the carbon leaching method for gold extraction Normally the CIL process can concentrate gold from 25–35 g/t in ore to 2000 to 6000 g/t on carbon CIL gold process is suitable for beneficiating oxidized gold ore with low sulfur and mud content It is characterized by low cost, short infrastructure construction time and CIL Gold Mining Process, Equipment Mineral Processing21 小时之前 Raw ore information in this silica sand washing project is as follows: 1 Raw sand contains 5% clay 2 Maximum feeding size of raw sand is 20mm 3 Finished silica sand size the customer need is less than 2mm 4 Raw sand contains 1% Fe2O3, customer’s requirement for removing Fe2O3 is less than 002% 5 Feeding capacity is 100 tons per Silica Sand Processing Plant Mineral Processing

Management and valorization of phosphate beneficiation

2023年4月29日 The mining industries produce phosphate rock with 28–31% of P 2 O 5 content The phosphate ore is generally separated from the minerals of granges in different steps using several processes After mining, the phosphate ore underwent a screening process onsite to separate the phosphate rock from the bulky mine wastes (onsite sand 2 天之前 The plate and frame filter press consists of chambers arranged alternately with filter plates and frames The feed pump hydraulically pumps the suspension into the filter chamber, and the filter residue is formed on the filter cloth until the filter chamber is filled to form a filter cake The filtrate passes through the filter cloth and flows Filter Press Mineral Processing2023年6月29日 Perforated vibrating screen can be used in the trommel screen machines Perforated vibrating screen is widely used in the flowing industries such as, crushed stone quarries, sand gravel plants, coal preparation plants, phosphate rock, iron ore mines, copper mines for screening coal, stones, gravels, sandPerforated Vibrating Screen for Screening Stones, Coal and

JXSC Mineral Processing Equipment Solutions

1 天前 Welcome To JXSC Mining Machinery We provide crushing, grinding, classifying, beneficiation, tailings treatment, laboratory and other processing equipment to global customers It is widely used in various Contribute to changjiangsx/ development by creating an account on GitHub/ ore vibrating screen ball mill for phosphatemd at 2021年2月4日 In 2020, phosphate rock ore was mined by five firms at 10 mines in four States and processed into an estimated 24 million tons of marketable product, valued at $17 billion, free on board (fob) mine Florida and North Carolina accounted for more than 75% of total domestic output; the remainder was produced inPhosphate Rock USGS Publications Warehouse

Screen Operator: A description for the screen operator job

2023年10月31日 Screen Operator: Tends series of vibrating screens that separate crushed ore or stone according to size: Pushes controls to start screens vibrating and move ore on conveyors or belts or splitter May also tend screens that separate phosphate rock from matrix and be designated FeedPreparation Operator (mining industry) Job industry: 2023年10月23日 Introduction: Mineral thickeners are recognized as the most costeffective equipment for water recovery from concentrate and tailings streams The concentrated slurry from the thickening process is transported to the tailings dam for disposal and the recycled water is returned to the processing plant In thickening (also called sedimentation Thickener Mineral Processing2023年10月23日 1 Coal Washing Plant (1) The excavator or loader feeds raw materials to the hopper of trommel scrubber; here trommel scrubber with 2layer screen at the end After washing off the clay, screen three outputs: above 50mm,2050mm, and below 20mm Above 50mm and 2050mm, outputs are transported to another place by belt conveyorsCoal Washing Plant, Equipment Mineral Processing

Wet Pan Mill JXSC Mineral

Wet Pan Mill also known as amalgamation grinding mill, gold grinder mill, which is a versatile ore grinding pan mill for wet materials It’s the best replacement for a mediumsmall capacity ball mill, owing to the excellent performance for wet crushing, small investment, and high output, widely used for separating gold, iron, molybdenum, lead, zinc, antimony, and so on2 天之前 Gold ore processing plants are common including washing screening, crushing grinding, beneficiation, concentrating, drying or smelting 1 Washing screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation 2 Crushing grinding: The content of gold in the Gold Processing Plant, Equipment Mineral Processing2 天之前 1 Washing: spiral washer Feed the raw sand less than 2mm into the raw ore bin, and directly feed it to the spiral washing machine to remove the impurities on the surface The silt floating surface can be overflowed together with the water The coarse ore particles sink to the bottom of the tank, and the bottom flow enters the vibrating screen 215TPH Zircon Sand Separation Plant In Kazakhstan

Quartz Sand VS Silica Sand Mineral Processing

2023年10月20日 Quartz sand is a quartz particle produced by crushing quartz stone Quartz stone is a nonmetallic, hard, wearresistant, and chemically stable silicate mineral The color of quartz sand is milky white, or colorless and translucent, with a Mohs hardness of 7 Quartz sand is an important industrial mineral raw material, nonchemical dangerous 2023年10月30日 Overview Introduction: The vibrating screen is a mechanical device for screening, classifying and filtering granular materials, commonly used in mining, industry and laboratories It is mainly used for Vibrating Screen Mineral Processing2023年10月28日 Wet pan mill is the optimal first grinding equipment for the majority of smallscale rock gold processing plants, alternative equipment for ball mills Wet pan mills are usually connected with equipment such as crushers, centrifuges, and shakers It is widely sold in most African countries such as Sudan and ZimbabweWet Pan Mill Mineral Processing

Factors That Affecting Shaking Table Gravity Separation

2023年10月20日 There are many factors affecting the work of the shaking table, among which the main stroke, the number of strokes, the concentration of ore feeding, the amount of ore feeding, the flushing water for the ore body, the lateral slope of the bed surface, and the nature of the ore feeding (1) Stroke and stroke times2023年11月1日 DMS(dense medium separation) is an efficient and widely used technique, especially useful for separating valuable minerals with relatively high gangue densitiesIt is often used in the processing of diamonds, coal and various base metal ores The mineral DMS process enables the mining industry to increase overall recovery efficiency by DMS Mining Process, Equipment Mineral Processing2023年10月20日 2 Grinding process The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing Here also need to use an auxiliary equipment – classifier It can classify and screen copper ore and release copper ore powder that meets the requirements 3Copper Ore Processing Plants, Flow And Equipment

Lead Zinc Processing Solution Mineral Processing

2023年11月1日 Leadzinc ore usually exists in the form of sulfide ores, such as sphalerite and galena Flotation is the most commonly used method The leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravityflotation, magneticflotation, and gravitymagnetic 2023年11月3日 1 Crushing: The material less than 15mm enters the hopper with a grizzly screen, then is fed by the trough feeder, and is transported to the jaw crusher and roller crusher through the belt conveyor, and is crushed twice to reach the ideal size 2 Screening: Qualified materials are screened by vibrating screen, materials less than 5mm enter the Tin Ore Processing Plant Mineral Processing2023年10月28日 JXSC Mine Machinery Factory Tel: +86 Email: sale@jxscmachine Phosphate Rock processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designPhosphate Rock Processing JXSC Machine

Cradletogate life cycle assessment of beneficiated phosphate rock

2022年1月21日 This study contributes to enlarge data about sedimentary phosphate rock extraction and beneficiation globally as currently only the USA and Morocco were reported in databases (1 kg crude ore contains 27% P 2 O 5), and the USA, where the average The scrubber, the vibrating screen, the hydrocyclone, and the filtration use electric 2019年10月25日 2 Vibrating washing screen vibrating screen product Mine use vibrating screens often adopts doublelayer screens for screening medium and fine crushed ore Add a highpressure water flushing device on the fixed screening machine The flushing water pressure is generally 0203 MPa, and the water consumption per ton of ore is 1 ~ 2 m3Ultimate Guide To Ore Washing JXSC Machine

Phosphate Rock Ore Vibrating Screen

Phosphate Rock Processing: 6 Useful Ways and 4 2023年8月8日 Phosphate rock is transported to the raw ore bin and enters the jaw crusher through the vibrating fe