-

صفحة رئيسية > المنتجات >

Ore crusher Steps Gold ore processing Plant

2020-10-06T01:10:36+00:00

Rock gold processing plant, gold ore processing plant

2020年7月18日 Stone crusher plant; Gold wash plant; Rock gold plant; ABOUT ABOUT US; WORKSHOP; FACILITIES; CONTACT; BLOG +86371 [ protected] 2023年1月19日 Currently,the gold ore processing methods are as follows: First of all, send the large gold ore to jaw crusher evenly and continuously for primary crushing by Gold Ore Crushing Process and Gold Crusher china1 天前 How we process and recover gold Extracting gold from the mined rock is a complex process From the time that the ore hoisted from underground and enters the processing plant, it takes up to five days Gold Fields South Deep Gold Mine How we

Gold Ore Processing Solution Eastman Rock

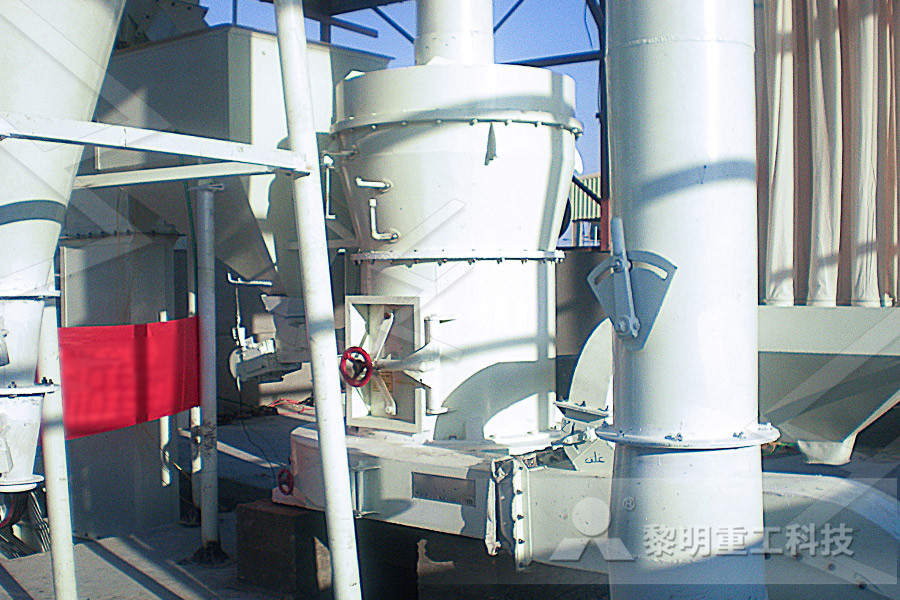

The process of gold ore processing and production mainly includes three processes: crushing, grinding and beneficiation2023年10月26日 Firstly, crush the gold ore with gold ore crusher and grind the crushed gold ore into powder with gold ore grinding mill Then extract the ore concentrate and tailings through gravity concentration and flotation Gold Ore Crusher/ Gold Ore Processing Plant/ 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to The six main steps of iron ore processing Multotec

Gold Processing Plant, Equipment Mineral

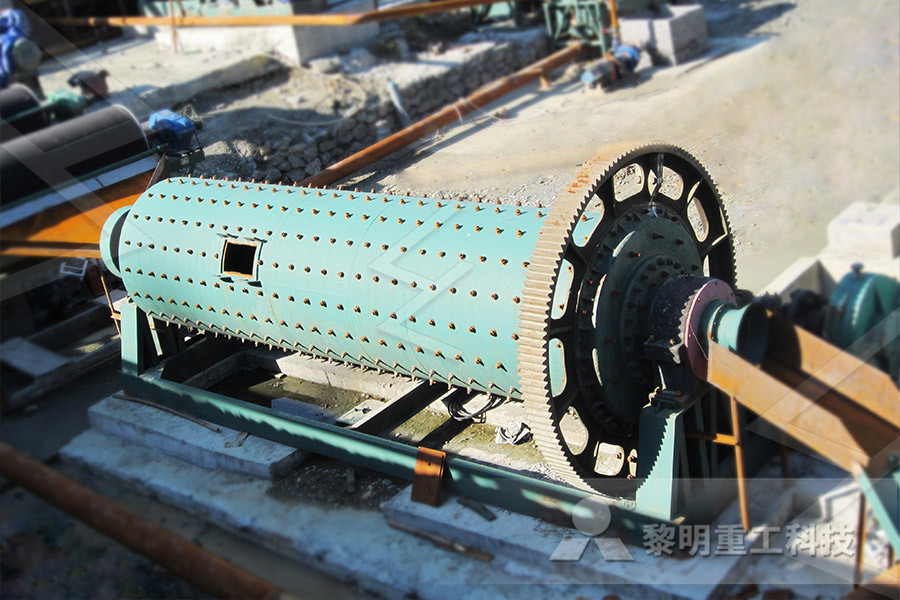

2 天之前 To extract gold, gold ore processing equipment crushes and grinds the ore and adopts ore dressing methods to preenrich or separate gold from the ore 3 Beneficiation stage: According to the characteristics 10 行 2023年9月28日 Ore Processing Plant is mainly composed of jaw crusher, ball mill, classifier,flotation machine, thickener, drier, feeder, and conveyor etc This Plant used for gold, copper, iron ore etc Process of Ore Processing Plant, gold ore processing plant, In 2016, 57 million tonnes of ore was delivered to the process plant RunofMine (ROM) ore is crushed and ground in semiautogenous (SAG) and ball mills, free gold is recovered in a gravity circuit and flotation is used to PorgeraJV Our Operation page Porgera Gold

Tungsten Processing 4 Successful Processing Plants

2023年3月24日 A tungstentin ore processing plant in Russia is an openpit mine located in the northern Caucasus The ore is a quartzcassiterite, wolframite, and clinopyroxene type mine Step #1 Crushing: The raw 2016年5月3日 Purchase Gold Ore Processing, Volume 15 2nd Edition Print Book EBook ISBN 84, 06 Books; Journals; Browse by subject Back Closure and Rehabilitation of GoldProcessing Plants 1 Process Closure and Cleanup; 2 Relocation and Sale – Owners' Perspectives; 3 Relocation and Sale – The Marketing Gold Ore Processing, Volume 15 2nd Edition Elsevier2019年7月22日 A typical Witwatersrand gold processing plant comprises twostage crushing and milling Milled ore is mixed with water prior to sodium cyanide leaching in aerated tanks These gold processing plants treat, on average, 150,000 t per month The plant recovery is usually better than 95% Au (SibanyeStillwater Limited 2017)Geometallurgical Approach for Implications of Ore Blending

Design of a crushing system that improves the crushing

2016年2月10日 The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 Crushers2022年7月5日 Lithium Processing Plant Release time:05 July 2022 Lithium is an element valuable for the production of glass, aluminum products, and batteries With the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly Therefore, lithium ore is known as the “energy metal Lithium Processing Plant JXSC Machine2016年2月24日 The process design criteria define the project’s production requirements, and typically include those shown in Table 1 Table 1 Production requirements Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive Crushing Plant Design and Layout Considerations 911

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日 38% Recovery rate 74% Manganese beneficiation machines: GZD850×3000 vibrating feeder,PE500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, Highstrength Magnetic drum separators 07 150 TPH Bauxite ore beneficiation plant in Indonesia 2 天之前 Gold ore processing plants are common including washing screening, crushing grinding, beneficiation, concentrating, drying or smelting 1 Washing screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation 2 Crushing grinding: The content of gold in the Gold Processing Plant, Equipment Mineral Processing2016年3月10日 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone Crushing Plant Flowsheet DesignLayout 911 Metallurgist

Diamond Processing Equipment, Process Flow,

2019年8月23日 Main factors influencing diamond processing flow 1 raw ore mineral composition and their properties 2 disseminated grain size 3 ore argillization property 4 surrounding rock fragmentation 5 content of 2023年10月27日 The process of mining for silver is broken down into three steps: removing ore from the earth, breaking it down and then flushing the silver from ore 167THP Crusher Plant and 42TPH Rock Gold Silver Mining Processing Equipment Flow Chart 2016年1月1日 Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition Implemented with tube autoclaves 15 km long and 5 cm inner diameter Leaching at ambient temperature and 5 MPa oxygen pressure and 02–05% NaCN; 15 min residence time for 85% recovery Cyanide oxidation negligibleSummary of Gold Plants and Processes ScienceDirect

5 Gold Extraction Methods to Improve Your Recovery Rate

2020年5月8日 The screening equipment is used to separate gold ores with proper size for the next steps The gold ore processing equipment in crushing and screen stage: jaw crusher,impact crusher, cone crusher,vibrating screen Ⅱ Ore Grinding Stage The beneficiation stage is a crucial part of gold extraction during the whole gold ore 2021年9月15日 Two jaw crusher factory pictures The crusher is a crushing machine used in the processing of metal ores and nonmetallic ores that can crush the mined raw ore into small particles by means of extrusion and bending In the actual production process, the production efficiency of the crusher is often affected by various reasons, which directly 8 Factors That Affect Production Efficiency of Crushers2022年10月9日 The application of CIP or CIL gold processing plant CIP or CIL method is suitable for processing the oxidized gold ore with high slime content 3 Confirm the capacity In this step, you shall consider how many ton of gold ore you will process per day or per hour, such as 100t/d, 200t/d or 300t/d, etc This is the foundation of design a CIP or CIP or CIL gold processing plant designZJH minerals

INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN

CRUSHING PLANT DESIGN The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: 1 Crusher selection 2 Crusher layout and 32021年9月8日 Abstract An analysis of flowsheets for processing sulfide and oxide copper ores, reagent modes, processing equipment, and flotation indicators in some domestic and foreign processing plants and productions is carried out Autogenous and semiautogenous mills are commonly used in the primary grinding stage in ore processing plants, which Current Status of CopperOre Processing: A Review2023年5月27日 Shaking table, also called gold recovery table or gold separation table, is the best fine gold recovery equipment It can process both gold ore in quartz rock, gold stones, and placer gold The feeding particle size range of the shaking table is generally between 3mm0019mm The gold beneficiation is stable and reliable, and the distribution 8 Pieces of Gold Mining Equipment to Get Gold Concentrates

Mica Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 Hardrock mining of micabearing ore requires drilling and blasting After blasting, the ore is reduced in size with drop balls and loaded on the trucks with shovels for transport to the processing plant, where mica, quartz and feldspar are extracted Jaw Crusher in the Mica Ore Beneficiation Processing Plant2023年10月31日 CIL (Carbon In Leach) is the carbon leaching method for gold extraction Normally the CIL process can concentrate gold from 25–35 g/t in ore to 2000 to 6000 g/t on carbon CIL gold process is suitable for CIL Gold Mining Process, Equipment Mineral 2023年11月2日 The chart/table below are crude budgetary estimations for the cost of major plant equipment Actual cost will vary depending of the process details and detailed equipment list and origin Please use this to Gold Processing Plants Complete Ore Process

Processing Côté Gold

Côté Gold’s processing plant incorporates triedandtested technology integrated with novel uses of established processes Ore processing capacity Total recovered gold: 918% Crushing A fleet of autonomous haulers feed the primary and secondary crushers A 54 x 75 primary gyrator crusher, which crushes ore at an average rate of 2,143 2016年5月25日 This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a Small Portable Gold Process Plant 911 Metallurgist2019年8月23日 This Setup is a Rock Chrome ore processing plant, it is configured with raw material feeding, primary crushing, fine crushing, screening, ball mill grinding, and gravity separation to separate out and upgrade Chrome concentrate The chrome ore raw material stone is fed to the primary jaw crusher by a vibration feeder to feed rock chrome ore Chromium Processing Process Flow, Cases JXSC Machine

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年11月2日 Ore processing is a 24 hour operation Ore is stockpiled at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added to raise its pH Following crushing through a jaw crusher, the ore is fed into the semi autogenous grinding (SAG) mill along with water and steel ballsProminer provides the complete solution of graphite processing plant including crushing, grinding and flotation plant to make natural flake graphite concentrate processing To get higher grade above TGC96% or even above TGC 9995%, deep processing should be applied General processing technologies for graphite ore are summarized as below Graphite Processing Plant Prominer (Shanghai) Mining Technology Co 2020年8月26日 There are many gold selection process schemes used in production practice, and the following are usually used: 01 Reselectioncyanidation combined process This process is suitable for processing quartz vein goldbearing oxide ore The raw ore is reselected first, and the concentrate obtained from the reselection is directly smelted; the Gold ore dressing method,beneficiation machine of gold ore

Iron Mining Process Equipment Flow Cases JXSC

2023年9月2日 Iron Ore Mining Process 1 Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing, the material will be transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for 1 天前 Lithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl (Si2O 5) 2, lepidolite K (Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl (SiO 3) 2 and also subsurface brines Australia and Chile are the world’s largest producers of lithiumLithium Mining Processing Equipment Flow Chart Cases2023年2月22日 What is a gold mining crusher plant? A gold mining crusher plant is a facility designed to crush and grind ore to extract the gold These plants typically include several stages of crushing, with each stage designed to break down the ore into smaller and smaller pieces for further processing What factors should be considered when designing Gold Mining Rock Crushers and Crushing Plants: A Complete

Mineral processing Metallurgy, Crushing

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a 2023年1月30日 Here are the steps involved: 1Exploration: Geologists locate and assess the presence of manganese ore deposits 2Mine Planning: Based on the survey results, engineers plan the mining process and How to do manganese mining LinkedIn2016年7月12日 Crushing Screening Plant Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable Crushing Screening Plant 911 Metallurgist

Minerals Free FullText SensorBased Ore Sorting

2019年7月8日 Graphical Abstract 1 Introduction Sensorbased ore sorting is gaining increased attention both within and outside the mining industry, as it is leaving the state of pilot plant scale and technology roadmapping, and an increasing amount of equipment is installed in highcapacity production scale environments2023年4月10日 The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves 5 Easy but Efficient Steps to Realize Manganese Ore Processing2017年9月7日 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 05 Clearly this is a function of gold price, but in the current gold Gold processing 101 Mining Magazine

Crushing and grinding process of copper ore Crusher Plant

2022年6月6日 The coarsely crushed copper ore is screened by a vibrating screen, and then sent to a singlecylinder hydraulic cone crusher (medium crushing) by a belt conveyor for medium and fine crushing Cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal minesThe first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 122 (based on Ref [4])This type of flow sheet is usually followed when the crude ore Crushing Circuit an overview ScienceDirect Topics2018年1月12日 Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals 13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facilityIntroduction to Mineral Processing or Beneficiation Sepro

PorgeraJV Our Operation page Porgera Gold

In 2016, 57 million tonnes of ore was delivered to the process plant RunofMine (ROM) ore is crushed and ground in semiautogenous (SAG) and ball mills, free gold is recovered in a gravity circuit and flotation is used to 2023年3月24日 A tungstentin ore processing plant in Russia is an openpit mine located in the northern Caucasus The ore is a quartzcassiterite, wolframite, and clinopyroxene type mine Step #1 Crushing: The raw Tungsten Processing 4 Successful Processing Plants2016年5月3日 Purchase Gold Ore Processing, Volume 15 2nd Edition Print Book EBook ISBN 84, 06 Books; Journals; Browse by subject Back Closure and Rehabilitation of GoldProcessing Plants 1 Process Closure and Cleanup; 2 Relocation and Sale – Owners' Perspectives; 3 Relocation and Sale – The Marketing Gold Ore Processing, Volume 15 2nd Edition Elsevier

Geometallurgical Approach for Implications of Ore Blending

2019年7月22日 A typical Witwatersrand gold processing plant comprises twostage crushing and milling Milled ore is mixed with water prior to sodium cyanide leaching in aerated tanks These gold processing plants treat, on average, 150,000 t per month The plant recovery is usually better than 95% Au (SibanyeStillwater Limited 2017)2016年2月10日 The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 CrushersDesign of a crushing system that improves the crushing 2022年7月5日 Lithium Processing Plant Release time:05 July 2022 Lithium is an element valuable for the production of glass, aluminum products, and batteries With the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly Therefore, lithium ore is known as the “energy metal Lithium Processing Plant JXSC Machine

Crushing Plant Design and Layout Considerations 911

2016年2月24日 The process design criteria define the project’s production requirements, and typically include those shown in Table 1 Table 1 Production requirements Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive 2021年3月24日 38% Recovery rate 74% Manganese beneficiation machines: GZD850×3000 vibrating feeder,PE500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, Highstrength Magnetic drum separators 07 150 TPH Bauxite ore beneficiation plant in Indonesia 10 Best Ore Beneficiation Plants for Sale (with Costs)2 天之前 Gold ore processing plants are common including washing screening, crushing grinding, beneficiation, concentrating, drying or smelting 1 Washing screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation 2 Crushing grinding: The content of gold in the Gold Processing Plant, Equipment Mineral Processing

Crushing Plant Flowsheet DesignLayout 911 Metallurgist

2016年3月10日 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone

Ore crusher Steps Gold ore processing Plant

Rock gold processing plant, gold ore processing plant 2020年7月18日 Stone crusher plant; Gold wash plant; Rock gold plant; ABOUT ABOUT US; WORKSHOP; FACILITIES;