-

صفحة رئيسية > المنتجات >

Sag Mill Circuit In Iron Ores

2023-01-30T14:01:11+00:00

(PDF) SAG mill circuit optimisation at Ernest Henry

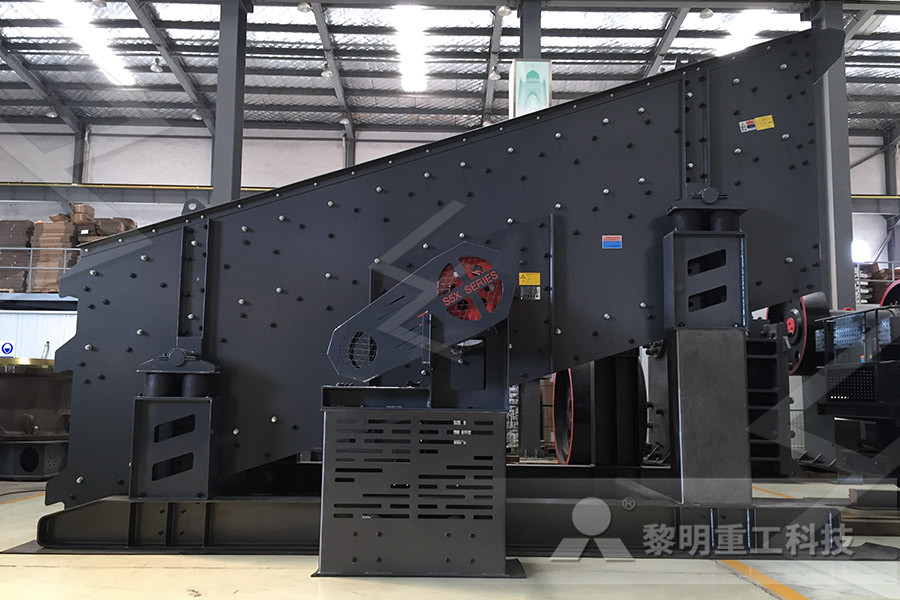

2001年9月1日 Table 4: JK MRC Comminution Parameters SAG milling in closed circuit with a vibrating screen followed by a ball mill OMC ARM 2021年3月15日 AG/SAG milling is technically feasible for grinding itabirites • Closed singlestage circuit was the most attractive in terms of grinding efficiency • Pebble Comparing strategies for grinding itabirite iron ores in 2023年9月30日 To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN; Use Add New Topic to ask a New Question/Discussion about Grinding; OR Select a SAG or Ball mill circuit in iron ore crushinggrinding

(PDF) Processing of Magnetite Iron

2009年1月1日 selected rather than screens to close the AG mill circuit for both and processed as ores to produce iron in an autogenous – 2022年1月1日 Many circuit configurations are possible, but essentially AG and SAG mills can be operated as a singlestage primary mill or can be followed by secondary milling in Comminution and classification technologies of iron oreThese circuits are not a good choice for many orebodies because it is not logical to expect one machine to be as efficient on "This paper describes the automation of Kiena's sag mill circuit in iron ores

sag mill circuit in iron ores

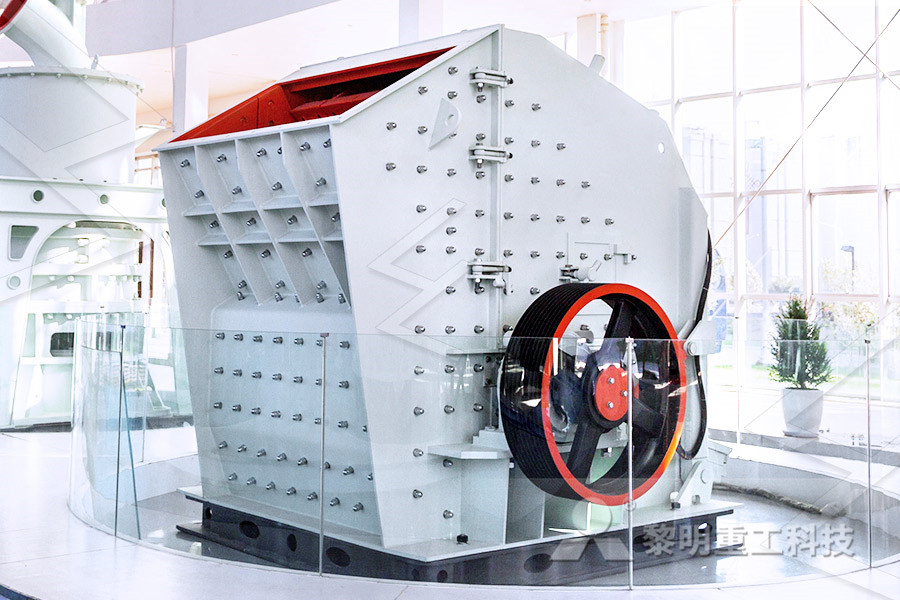

The SAG Mill is a machine added by Ender IOIt uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into DustsThe SAG Mill has four output slots; The high unit capacity SAG mill/ball mill circuit is dominant today and has contributed toward substantial savings in capital and operating costs, which has in turn made many sag mill circuit in iron ores MC MachineryExamples of SAG mill in a sentence It includes single stage jaw crushing with reclaim from a live stockpile and open circuit SAG mill, feeding cyclones that in turn operate in a SAG mill Definition Law Insider

Comminution and classification technologies of iron ore

2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) products2010年7月1日 Pebble crushing is an arduous duty in a SAG mill circuit The trend to installing larger pebble crushers capable of crushing up to 70100 percent of the new feed rate has been observedThe Evolution of Crushing and Grinding: Changes in the Industry 2022年6月17日 Semiautogenous (SAG) mills are widely used grinding equipment, but some ore with critical particle sizes cannot be effectively processed by SAG mills and turned into pebbles This research aims to analyze and compare the properties of raw ore and pebbles from a zinc and tinbearing ore The results show that the contents of sphalerite, Differences in Properties between Pebbles and Raw Ore from a SAG Mill

Comminution Circuit Design and Simulation for the

2017年5月27日 • Details the development of the SAG circuits and explains how the new generation of crushing circuits, with HPGR for tertiary crushing, are starting to replace SAG circuits in hardrock mining • Presents a structured methodology for comparison of the energy requirements for HPGR versus SAG complete circuits2016年6月6日 AG/SAG throughput is defined by the unit power required to grind the ore to the closing size attained in the circuit Very hard ores can severely constrain AG/SAG mill throughput In such cases, the circuits can become capital inefficient (in terms of the size and number of primary milling units required) and can require more total power input SAG Mill Grinding Circuit Design 911 MetallurgistTracking the mill performance showed that the mill power consumption decreased from 949 to 663 kWh/t (a nearly 30% reduction), P80 of the mill product decreased from 611 to 355μm, and the mill Typical AG/SAG breakage rate function ResearchGate

Technical and economic assessment of a nonconventional HPGR circuit

2017年4月1日 Introduction The application of HPGR technology in comminution circuits is well established for the processing of cement, diamonds and iron ore (Broeckmann and Gardula, 2005), and over the past 10–15 years, this technology has slowly been applied to hard ores in hightonnage precious and base metal operationsUnfortunately, under the 2020年10月20日 Approximately 3000 tons of large lumps of ore with particle size in the range of 200–500 mm were transferred to the AG mill feed stockpile from another processing unit of the Sangan iron ore processing plant (Fig 2 a)From this stockpile they are conveyed by a belt conveyor to the AG mill (Fig 2 b), and the percentage of coarse The performance improvement of a fullscale autogenous mill by setting The crushingball milling circuit specific energy was estimated on the basis of the Bond equation and the relevant Bond work indices (Table 4), with the crushing energy given from the SAG/AG F80 AG/SAG mill throughput vs specific Energy ResearchGate

How energy efficient is HPGR?

2018年2月20日 platinum, PGMNiCu and iron ores HPGR technology is discussed with respect to energy efficiency The harder the ore the greater the energy savings are likely to be circuits vs SAG/Ball Mill circuits are generally beneficial but nothing like as advantageous as this, however the above number offers a big incentive to plant paring strategies for grinding itabirite iron ores in autogenous and semiautogenous pilotscale mills (SAG) ball mill crushing (SABC) circuits has introduced a complex materials Malcolm POWELL Professor (Full) PhD The University2023年6月27日 In a largescale operation, feed ores are introduced into the AG/SAG mill in a continuous mode at a given flow rate to replace the discharging slurry Nonetheless, the variations in the feed characteristics, Acoustic Sensing of Fresh Feed Disturbances in a

Comparing strategies for grinding itabirite iron ores in

2021年3月15日 Between 1993 and 2003, a series of AG and SAG mill pilot plant trials were conducted using Hardinge Ical pilot plant scale SAG mills on numerous ore samples and ranging across a wide variety of 2022年6月6日 A total of 120 t of Cristalino ore was prepared and sent to CIMM, where it was crushed and screened prior to grinding tests The processing equipment included a 183 m (8′) diameter by 061 m (2′) length AG/SAG mill equipped with a 20 kW motor, a cone crusher, a 091 m (3′) diameter by 122 m (4′) length ball mill equipped with a 15 kW PreProcessing to Increase the Capacity of SAG Mill Circuits2022年7月13日 grinding circuits, ball and rod mill circuits, and crushing circuits are also available for testing and design purposes Inplant audits allow modeling and simulation of existing plants to assist in optimization Rotary scrubbers and attrition scrubbers are available to test lateritic iron ores PHYSICAL MINERAL SEPARATION / BENEFICIATIONSGS STATEMENT OF CAPABILITIES FOR IRON ORE

Net specific energy consumption in AG/SAG circuit against

The crushingball milling circuit specific energy was estimated on the basis of the Bond equation and the relevant Bond work indices (Table 4), with the crushing energy given from the SAG/AG F80 2015年8月1日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills are widely used for the grinding of competent base metal ores (such as copper) and iron ore in the minerals industry, and have become standard equipment in comminution circuits In an AG/SAG mill operation, some competent rocks with an approximate size range of 20–75 Preconcentration of copper ores by high voltage pulses2010年1月1日 Iron (Fe) ores play a significant role in the global mining industry judging by the high tonnes of ore followed by a ball mill and pebble crusher in a SAG/AG, ball mill circuit for most (PDF) Reducing Grinding Energy and Cost Magnetite Iron

Improving energy efficiency in comminution

2018年10月1日 In this case, an AG or SAG mill may be appropriate For smaller throughput scenarios, a threestage crushing plus rod mill plus Vertimill may make the most sense It all depends on the ore 2023年6月28日 The Bond Ball Mill Grindability Test is performed according the original Bond procedure It requires 10 kg of minus 6mesh material that is preferably prepared at the testing facility The Bond Ball Mill Work Index has been widely used for ball mill sizing, and is also utilized in computer simulation BOND ROD MILL GRINDABILITY TESTSGS MINERALS SERVICES – T3 SGS 960 112009SAG Mill Circuit Example — Gold Processing SAG mill circuit example for gold processing [image: (13563)] AG/SAG Mill AG/SAG mills are normally used to grind runoffmine ore or primary crusher product Wet grinding AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

PreProcessing to Increase the Capacity of SAG Mill Circuits

2022年6月6日 This paper describes the adopted approach for increasing the capacity of an existing industrial grinding circuit by adapting the respective configuration to process the ore from a new mine Accordingly, due to Sossego mine exhaustion, Vale S A decided to use the existing industrial facilities and infrastructure for processing the Cristalino ore deposit A hammer sampler is used to sample the feed and an overbelt magnet is used to remove any tramp iron from the feed, before going to the SAG mill Water is added to the SAG mill circuit to facilitate slurry being transferred Copper Processing Multotec2019年6月28日 If the ore rock is highly fractured and/or brittle, it is likely that an AG mill be the most economical option in lieu of a SAG mill AG milling can produce a finer grind than SAG milling for certain ores Figure 2 summarizes the different comminution circuits and some relative factors compared to the other methodsGold extraction QueensMineDesignWiki

(PDF) OPTIMISATION OF THE SOSSEGO SAG MILL

2006年9月23日 The comminution circuit was designed to treat 41 000 metric tons per day comprising primary crushing, one 116 m SAG mill operating in closed configuration with cone crushers, followed by two 67 2022年3月25日 grinding circuits, ball and rod mill circuits, and crushing circuits are also available for testing and design purposes Inplant audits allow modeling and simulation of existing plants to assist in optimization Rotary scrubbers and attrition scrubbers are available to test lateritic iron ores PHYSICAL MINERAL SEPARATION / BENEFICIATIONStatement of Capabilities for Iron Ore SGS2020年11月1日 Much of the remaining iron ore resources in Brazil consist of lowgrade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and Comminution and liberation response of iron ore types in a

PreProcessing to Increase the Capacity of SAG Mill

2023年9月21日 Minerals 2022, 12, 727 3 of 12 13 Sossego Grinding Circuit In 2004, Vale started the Sossego mine in Canaã dos Carajás, Pará state, in the Brazilian Amazon The industrial plant was designed 2023年8月1日 Much of the remaining iron ore resources in Brazil consist of lowgrade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and Transforming iron ore processing ScienceDirect2010年3月1日 The process enables the application of energyefficient HPGR to base and precious metal hardores containing clay, which are usually processed using SAG mill circuitsThe work presented in this A structured approach to the evaluation of the energy

Schematic diagram of AG/SAG mill process

Tracking the mill performance showed that the mill power consumption decreased from 949 to 663 kWh/t (a nearly 30% reduction), P80 of the mill product decreased from 611 to 355μm, and the mill This study focussed on flowsheet simulation for mineralogicalbased approach to geometallurgy of iron ores Process unit models used were selected based on their applicability at particle level for iron ore Process simulations in mineralogybased 2 天之前 sized materials, once the domain of tower and ball mills The need for energy efficient grinding circuits will only result in more IsaMill™ circuits being applied in the future IsaMill™ OPERATION Grinding Mechanism The IsaMill™ is a horizontally stirred mill consisting of a series of 8 discs rotating around a shaftIsaMill Technology Used in Effecient Grinding Circuits

Grinding Circuit an overview ScienceDirect Topics

The high unit capacity SAG mill/ball mill circuit is dominant today and has contributed toward substantial savings in capital and operating costs, which has in turn made many lowgrade, hightonnage operations such as copper and gold ores feasible Future circuits may see increasing use of high pressure grinding rolls (Rosas et al, 2012)2023年11月1日 Cerro Verde actual data shows that the HPGR circuit energy consumption was 3 kWh/t less than the SAG/Ball mill circuit that was considered in the trade off studies This can solve many problems of handling and metallurgical problems of processing ores Examples In Iron ore Hematite if you grind more recovery is less, Blaine if it exceeds HPGR vs SAG Grinding Classification Circuits2011年2月1日 The process enables the application of energyefficient HPGR to base and precious metal hardores containing clay, which are usually processed using SAG mill circuits The work presented in this paper involved laboratory testwork including pilot HPGR testing, and modelling and simulation of both the HPGRbased circuit and an equivalent A preliminary investigation into the feasibility of a novel

SAG 2015 Conference Update ceecthefuture

2018年2月20日 New projects in Russia for Hard and Soft Ores with SAG Mills Selected from the Results of SAGDesign Testing Arkady Senchenko Operation and Process Optimisation of Sino Iron’s AG Milling Circuits JianjunTian Bringing Life Back to Pueblo Viejo – Ore Grinding Equipment Selection, Design, Construction, and CommissioningThe likely response of a standard SAG mill circuit treating a competent ore (A*b = 35) to a partial midsize precrush is simulated in JKSimMet, with key data presented in the circuit overview of SAG mill compared to crusher and ball mill product size 2021年6月24日 raising the availability to > 94% to match those of SAG mills The large scale test currently being conducted on a hard abrasive gold ore will prove that this technology is now ready to challenge conventional circuit design Maximum feed size vs roll diameter 0 10 20 30 40 50 60 70 80 05 10 15 20 25 Roll diameter [ m ]] mdot = 200 High Pressure Grinding Rolls for Minerals AusIMM

Energy Requirements of HPGR and SAG Circuits

2018年2月20日 Currently, after many years of SAG application, it has been recognized and demonstrated that the inclusion of pebble crushing in hard ore SAG circuits results in substantial energy savings (Vanderbeek, 2004) Since for this research the JK A*b parameters and their Positions in JKTech’s database indicate both ores are hard, SABC 2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) minution and classification technologies of iron ore2010年7月1日 Pebble crushing is an arduous duty in a SAG mill circuit The trend to installing larger pebble crushers capable of crushing up to 70100 percent of the new feed rate has been observedThe Evolution of Crushing and Grinding: Changes in the Industry

Differences in Properties between Pebbles and Raw Ore from a SAG Mill

2022年6月17日 Semiautogenous (SAG) mills are widely used grinding equipment, but some ore with critical particle sizes cannot be effectively processed by SAG mills and turned into pebbles This research aims to analyze and compare the properties of raw ore and pebbles from a zinc and tinbearing ore The results show that the contents of sphalerite, 2017年5月27日 • Details the development of the SAG circuits and explains how the new generation of crushing circuits, with HPGR for tertiary crushing, are starting to replace SAG circuits in hardrock mining • Presents a structured methodology for comparison of the energy requirements for HPGR versus SAG complete minution Circuit Design and Simulation for the 2016年6月6日 AG/SAG throughput is defined by the unit power required to grind the ore to the closing size attained in the circuit Very hard ores can severely constrain AG/SAG mill throughput In such cases, the circuits can become capital inefficient (in terms of the size and number of primary milling units required) and can require more total power input SAG Mill Grinding Circuit Design 911 Metallurgist

Typical AG/SAG breakage rate function ResearchGate

Tracking the mill performance showed that the mill power consumption decreased from 949 to 663 kWh/t (a nearly 30% reduction), P80 of the mill product decreased from 611 to 355μm, and the mill 2017年4月1日 Introduction The application of HPGR technology in comminution circuits is well established for the processing of cement, diamonds and iron ore (Broeckmann and Gardula, 2005), and over the past 10–15 years, this technology has slowly been applied to hard ores in hightonnage precious and base metal operationsUnfortunately, under the Technical and economic assessment of a nonconventional HPGR circuit 2020年10月20日 Approximately 3000 tons of large lumps of ore with particle size in the range of 200–500 mm were transferred to the AG mill feed stockpile from another processing unit of the Sangan iron ore processing plant (Fig 2 a)From this stockpile they are conveyed by a belt conveyor to the AG mill (Fig 2 b), and the percentage of coarse The performance improvement of a fullscale autogenous mill by setting

AG/SAG mill throughput vs specific Energy ResearchGate

Much of the remaining iron ore resources in Brazil consist of low grade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by 2018年2月20日 platinum, PGMNiCu and iron ores HPGR technology is discussed with respect to energy efficiency The harder the ore the greater the energy savings are likely to be circuits vs SAG/Ball Mill circuits are generally beneficial but nothing like as advantageous as this, however the above number offers a big incentive to plant designersHow energy efficient is HPGR?

Sag Mill Circuit In Iron Ores

(PDF) SAG mill circuit optimisation at Ernest Henry 2001年9月1日 Table 4: JK MRC Comminution Parameters SAG milling in closed circuit with a vibrating screen fo