-

صفحة رئيسية > المنتجات >

Maintenance Schedules For Mining Equipment

2020-12-14T16:12:15+00:00

Mining Equipment Maintenance Copeland International

2020年4月24日 Here’s your guide to conserving your mining equipment Each conveying system, vehicle, or tool needs routine maintenance to prevent losing thousands of dollars From machine lubrication to regular maintenance schedules, and safety training; mining PDF On Jan 1, 2014, Kovalev Vladimir and others published Preventive Maintenance of Mining Equipment Based on Identification of Its Actual (PDF) Preventive Maintenance of Mining 2023年6月9日 Periodic Maintenance for Mining Equipment Regular maintenance tasks are essential for efficient operation in mining equipment Daily checks help identify immediate issues and ensure safety before Comprehensive Guide to Mining Equipment

(PDF) Maintenance Schedules of Mining HEMM

2019年9月26日 The new key performance indicators can be measured as “Mean Time of Preventive Maintenance” and “Mean Time of Overall 2023年11月3日 The mining industry incorporates the use of technology and equipment on an everyday basis Ensuring that equipment is Tips for Proper Maintenance of Mining Equipment2020年8月3日 This paper proposes an effective maintenance management approach to be used in the mining industry such that equipment availability and reliability are improved Optimal Inspection and Preventive Maintenance Scheduling of Mining

Mining Equipment Maintenance SpringerLink

The chapter presents various important aspects of mining equipment maintenance including maintenancerelated facts and figures, factors contributing to equipment maintenance 2021年1月20日 Use this heavy equipment maintenance schedule template to proactively schedule maintenance for your equipment and keep tabs on successive maintenance Enter each piece of equipment’s name, brand, Free Equipment Schedule Templates SmartsheetIn this article, we will explore the importance of maintenance schedules for mining equipment and how they can contribute to the success of your mining operation So let’s maintenance schedules for mining equipment – stone cruxder

Maintenance services and repairs for mining

offers comprehensive maintenance and repair services for mining equipment, from inspections to shutdowns to emergency fixes Click to explore! For equipment used in the mining and metals industry2022年11月9日 Preventive maintenance practices have been proven to reduce maintenance costs in many industries In the mining industry, preventive maintenance is the main form of maintenance, especially for Mining Free FullText Current Practices for 2020年8月3日 In turn, preventive maintenance of mining equipment was described by Angeles et al [23] Topal et al drew attention to the high operating costs associated with the use of wheeled transport and Optimal Inspection and Preventive Maintenance Scheduling of Mining

Cat® Equipment Maintenance and Repairs Cat

21 小时之前 Cat ® Equipment Maintenance Repairs Keep your Cat® equipment in top condition and ready to work Your local Cat dealer can provide fast, professional service for planned equipment maintenance 2023年10月9日 Maintenance Schedules of Mining HEMM Using an Optimization Framework Model Niraj Ranjan Sharma 1 , Hemant Agrawal 2* , Arvind K Mishra 1 1 Indian Institute of Technology (ISM), Dhanbad , IndiaMaintenance Schedules of Mining HEMM Using an2020年8月12日 This paper presents an algorithm for optimizing the scheduling of trackless equipment in underground mines With the shortest working interval and maximum productivity as goals, a genetic algorithm (GA) is used to solve the problem, and obtain the optimal working sequence with the most suitable equipment configuration possible The Optimization of Trackless Equipment Scheduling in

Bryton Sibanda Shift Millwight PPC Zimbabwe LinkedIn

I'm a highly innovative Class One Millwright artisan with experience in providing various mechanical and electrical equipment’s support, maintaining optimum functionality for plant equipment by performing inspections, completing preventive maintenance schedules, installation and servicing of plant machinery,with traceable years of experience in open 2020年1月1日 In order to gain a competitive edge, firms have to implement stateoftheart asset management systems and optimise maintenance strategies and policies for their equipment While maintenance planning and optimisation is the subject of extensive research for decades (Dekker, 1996; Marseguerra and Zio, 2000; Budai et al, 2008; de Maintenance schedule optimisation for manufacturing systems2023年6月15日 haul roads and equipment as well as operator experience to lower cycle times by about 8% [11] Finally, Samatemba et al recently employed equations to discover the utilization rate, production rate, equipment availability, efficiency, and performance rate for haul trucks, loaders, and drill rigs in Chibuluma South Mine in Zambia [12] With simpleData Analyses of Quarry Operations and Maintenance

Data Analyses of Quarry Operations and Maintenance Schedules

2023年4月18日 The development of new technologies has opened a broader view into machines and sensors through the expanded collection of big data The Internet of Things (IoT) has taken hold in the mining industry, allowing connections between equipment and software to produce realtime data on numerous operation parts: hazard analysis, fleet 2021年9月24日 The majority of mining operations run 365 days a year to meet customer demand Therefore, uptime of mining equipment is critical Any unplanned downtime can dramatically impact productivity and profitability There are many assets used for mining operations, including excavators, dozers and dump trucks Dump trucks used in mining Predictive Maintenance for Mining Vehicle Applications2008年2月1日 The maintenance scheduling for manufacturing systems proposed in [15] considers the product quality and the maintenance cost including the repair and preventive maintenance cost (PDF) Maintenance scheduling in manufacturing

Maintenance Schedules of Mining HEMM Using An Opti

2022年10月21日 The new key performance indicators can be measured as “Mean Time of Preventive Maintenance” and “Mean Time of Overall Maintenance” which will plot the maintenance schedule pattern for analysis and will combine the planned and unplanned maintenance schedules, subsequently improving the availability of the mining equipment Maintenance is an important element of mining equipment life cycle The chapter presents various important aspects of mining equipment maintenance including maintenancerelated facts and figures, factors contributing to equipment maintenance cost in mines, maintenance of explosion protected switchgear in mines, useful maintenance measures for mines, and Mining Equipment Maintenance SpringerLinkMaintenance scheduling is the management and allocation of maintenance tasks It should be decided when the maintenance tasks are conducted and by whom Optimization plays a critical role in the efficient usage of the equipment or machinery being maintained The optimization of maintenance schedules can yield significant savings for companiesFull article: Optimizing the maintenance schedule for a vehicle

Germain Tai MAINTENANCE SCHEDULER Newcrest Mining

Daily weekly preventive Maintenance Schedules of fleets to ensure maximum availabilities for productionPrepare issue daily planned jobs for workshop supervisors workshops crew before preshift morning meeting monitor scheduled jobsProduce equipment performance reports KPI'S for maintenance mining 2019年9月4日 Topal and Ramazan [Citation 18, Citation 19] propose an MIP formulation to minimise the maintenance cost of using mining equipment under the assumption that the cost varies with equipment age Burt et al [ Citation 20 ] develop a methodology for purchasing and salvaging equipment for longterm mine production, given that equipment Full article: Incorporating geological and equipment 1 天前 54+ Maintenance Schedule Template – Free Word, Excel, PDF Format Download A maintenance schedule tells and records weekly, monthly, quartely, and yearly property and facility repairs and checkups needed for your equipment to work and operations to run smoothly For some, writing a schedule can be challenging When working in a plant, 54+ Maintenance Schedule Template Free Word, Excel, PDF

Data Analyses of Quarry Operations and Maintenance Schedules

2023年6月15日 Data Analyses of Quarry Operations and Maintenance Schedules: A Production Optimization Study Mining 2023, 3(2), 347366; The analysis of the literature in the field of mining machinery maintenance, data acquisition methods, and machine methods used for mining machinery should definitely be enlarged Mining 2023; 2023年4月27日 Equipment failure is a common problem in mining operations, resulting in significant delays and reductions in production efficiency To address this problem, this paper proposes a dynamic scheduling model for underground metal mines under equipment failure conditions The model aims to minimize the impact of equipment failures on A Dynamic Scheduling Model for Underground Metal Mines under Equipment 2022年8月30日 Cause #1: Improper operation Cause #2: Failure to perform preventive maintenance Cause #3: Too much preventive maintenance Cause #4: Failure to continuously monitor equipment Cause #5: Bad (or no) reliability culture The bottom line Equipment failure happens The impact of it can run the gamut from easily fixed with 5 Causes Of Equipment Failure And How To Prevent Them

A new MIP model for mine equipment scheduling by minimizing maintenance

2010年12月1日 A new MIP model has been proposed to provide substantial cost savings for equipment scheduling by optimizing truck usage The MIP model used for this case study provides a saving of approximately $156M in discounted cash costs for the first 5 years and $213M over the 10 year mine life While it is not possible to predict precisely the savings 21 小时之前 The underground jumbo drill rigs from Epiroc are used for blast hole drilling in underground mining and tunneling The rigs are equipped with up to four booms, covering cross sections from 6 m 2 to 206 m 2We offer underground jumbo drill rigs with our reliable Direct Control System, DCS, or with the computerized Rig Control System, RCS, to Underground Face and Jumbo Drill Rigs for Mining and 2 天之前 Preventive maintenance can reduce machinery repair bills by 25 percent An example is an $80,000 machine that requires approximately $24,000 in maintenance and repair costs during 5,000 operating hours Maintenance Tips for Heavy Equipment

Machine Learning Applications on Predictive Maintenance

2022年4月28日 Here, predictive maintenance allows for remote configuration of the machine and smoothrunning maintenance The older equipment is modified with IoT capabilities as well FritoLay The snack food manufacturer and PepsiCo’s subsidiary, FritoLay, has a successful track record of launching a sophisticated PdM technology initiative 2013年4月3日 General Kinematics, a mining equipment manufacturer, is a key player in the field of safe and effective mining equipment The rugged design of GK equipment reduces maintenance requirements by utilizing easily accessible machinery and few moving parts This allows safer access to maintenance personnel The heavyduty design is also Improving Mining Equipment Maintenance and Safety2023年6月9日 Benefits of Daily Drilling Equipment Maintenance Checks Performing daily equipment maintenance checks before using the drilling rig is a proactive measure to identify potential malfunctions and prevent accidents The benefits of conducting these checks include: Early Detection of Issues: Daily maintenance checks help identify issues at an Comprehensive Guide to Drilling Rig Maintenance

Performance Evaluation of Underground Mining Machinery:

2020年8月19日 (a) (b) A typical LHD machine at the workshop and during the repair action Before performing the reliability analysis, each machinery must be categorized into several subsystems for identifying potential failure modes []Theses categorizations were made based on past historical records like daytoday worksheets maintained by 2019年6月30日 Underground Mining equipment list Soft rock mines, such as coal, do not require the use of explosives for extraction These rocks can be cut with the mining tools provided by modern technology Soft rocks are also salt, potash, and bauxite In hard rock mines, extraction is carried out by drilling and blastingMINING Equipment List Mining Tools Names2023年6月30日 Optimization of Quarry Operations and Maintenance Schedules Brennan K George ABSTRACT New technologies such as the Internet of Things are providing newer insights into the health, performance, and utilization of mining equipment through the collection of realtime data with sensors In this study, data is utilized from multiple Optimization of Quarry Operations and Maintenance

Predictive Maintenance Scheduling with AI and Decision

2018年6月17日 The idea is to use this information to schedule maintenance before equipment fails but not before it is actually needed, avoiding unnecessary costs associated with repair and production loss (Figure 1) Depending on the industry, the type of assets can vary from cars and trucks to wind turbines, cranes, and oil platforms 2023年6月6日 The mining industry is a critical sector that relies on the efficient operation of heavy machinery and equipment to ensure productivity and safety Preventative maintenance plays a crucial role in Preventative Maintenance in Mining with Digital 23 小时之前 Equipment history and data: The equipment's history and data should also be considered a tool because this information helps you figure out the proper maintenance required based on uptodate or even real Maintenance Planning and Scheduling: An

Tips to Improve Maintenance in Mining and Metal Industry

2020年12月23日 1 Providing Upkeep on Time Every asset is crucial in the mining industry and to keep it working it should be well maintained These assets perform activities that are intensive work so maintenance is significant even a small issue can be drastic for the organization Thus, providing maintenance on time is important2017年8月26日 and schedules the available fleet to meet the annual production targets The scheduling has been performed by applying both the proposed stochastic and deterministic approaches The approach provides a distribution for the maintenance cost of the optimized equipment schedule minimizing the costMining truck scheduling with stochastic maintenance 2022年10月6日 Mining equipment is monitored, using sensors and analytics to calculate machine maintenance and repair cycles, while robotics and autonomous vehicles are used to replace labour in mines From the vital equipment in the mines themselves to all the backend apps and systems in the data centre or cloud, IT has taken centre stage in every Mining equipment monitoring systems help make machines

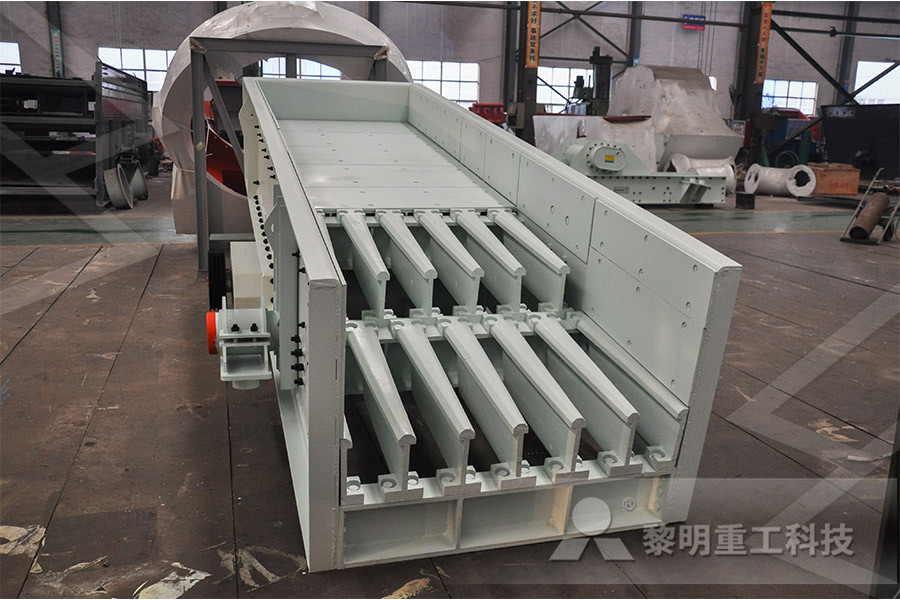

Surface Mining Equipment Overview Vector Solutions

2018年2月10日 Stationary equipment at a surface mine typically performs hauling, processing, and other service functions Structures provide offices, storage, and maintenance spaces The following stationary equipment and structures are common to most surface mining operations: Conveyor systems Feeders, bins, and hoppers 2023年5月31日 Each selective mining unit (SMU), or block, has a known position, metal grade(s), and tonnage An area represents a predefined region of the mine comprised a large grouping of blocks In this optimisation model, areas are used to define equipment positions, origins for truck cycle times, and long shovel movements with an associated Incorporating geological and equipment performance Easily organize, track, and optimize asset performance Managing your assets shouldn’t be guesswork Fiix’s asset management module lets you easily see and manage all equipment information in one place— everything from repair history and cost, to hierarchy, parts consumption, and more Based on 800+ reviews onAsset Maintenance Management Software Fiix CMMS

Rig Maintenance Drillingsoftware

Windows 7 WMV video A complete system of check lists covering all aspects of maintenance for both Drilling and Workover rigs from the crown to the ground and for land rig operations, includes heavy equipment, bulldozers, cranes tool pusher and crew vehicles A complete maintenance system for mechanical and electrical equipment2015年12月1日 Abstract Heavy earth moving equipment's are critical for completion of any developmental projects Dams, schools, bridges or any mining related initiations are part of these infrastructure (PDF) MAINTENANCE SYSTEM FOR HEAVY EARTH MOVING EQUIPMENT 2022年11月9日 Preventive maintenance practices have been proven to reduce maintenance costs in many industries In the mining industry, preventive maintenance is the main form of maintenance, especially for Mining Free FullText Current Practices for

Optimal Inspection and Preventive Maintenance Scheduling of Mining

2020年8月3日 In turn, preventive maintenance of mining equipment was described by Angeles et al [23] Topal et al drew attention to the high operating costs associated with the use of wheeled transport and 21 小时之前 Cat ® Equipment Maintenance Repairs Keep your Cat® equipment in top condition and ready to work Your local Cat dealer can provide fast, professional service for planned equipment maintenance Cat® Equipment Maintenance and Repairs Cat2023年10月9日 Maintenance Schedules of Mining HEMM Using an Optimization Framework Model Niraj Ranjan Sharma1, Hemant Agrawal2*, Arvind K Mishra1 1 Indian Institute of Technology (ISM), Dhanbad , India 2 Maintenance Schedules of Mining HEMM Using an

Optimization of Trackless Equipment Scheduling in

2020年8月12日 This paper presents an algorithm for optimizing the scheduling of trackless equipment in underground mines With the shortest working interval and maximum productivity as goals, a genetic algorithm (GA) is used to solve the problem, and obtain the optimal working sequence with the most suitable equipment configuration possible The I'm a highly innovative Class One Millwright artisan with experience in providing various mechanical and electrical equipment’s support, maintaining optimum functionality for plant equipment by performing inspections, completing preventive maintenance schedules, installation and servicing of plant machinery,with traceable years of experience in open Bryton Sibanda Shift Millwight PPC Zimbabwe LinkedIn2020年1月1日 In order to gain a competitive edge, firms have to implement stateoftheart asset management systems and optimise maintenance strategies and policies for their equipment While maintenance planning and optimisation is the subject of extensive research for decades (Dekker, 1996; Marseguerra and Zio, 2000; Budai et al, 2008; de Maintenance schedule optimisation for manufacturing systems

Data Analyses of Quarry Operations and Maintenance

2023年6月15日 haul roads and equipment as well as operator experience to lower cycle times by about 8% [11] Finally, Samatemba et al recently employed equations to discover the utilization rate, production rate, equipment availability, efficiency, and performance rate for haul trucks, loaders, and drill rigs in Chibuluma South Mine in Zambia [12] With simple2023年4月18日 The development of new technologies has opened a broader view into machines and sensors through the expanded collection of big data The Internet of Things (IoT) has taken hold in the mining industry, allowing connections between equipment and software to produce realtime data on numerous operation parts: hazard analysis, fleet Data Analyses of Quarry Operations and Maintenance Schedules2021年9月24日 The majority of mining operations run 365 days a year to meet customer demand Therefore, uptime of mining equipment is critical Any unplanned downtime can dramatically impact productivity and profitability There are many assets used for mining operations, including excavators, dozers and dump trucks Dump trucks used in mining Predictive Maintenance for Mining Vehicle Applications

Maintenance Schedules For Mining Equipment

Mining Equipment Maintenance Copeland International 2020年4月24日 Here’s your guide to conserving your mining equipment Each conveying system, vehicle, or tool